A freight carrier are legal licensed individual or business that specialises in moving cargo from one. location to another. According to each carrier’s mode of operation, freight carriers are typically divided into a wide range of divisions.

Some businesses might manage the shipping of goods from one nation to another as a global freight forwarder. On the other hand, the internal transportation of goods refers to the movement of goods from one city or town to another within a nation. Another type of economic activity involves the international and domestic transportation of goods.

To transfer goods, shipping companies employ a variety of transport systems. Whether moving by land, rail, water, or air, carriers typically focus on a single mode. Certain freight carriers offer multi-modal service to deliver goods using a variety of modes of transportation. Cost, timing, and cargo information are the primary factors influencing multimodal transportation services. How to choose a method of

transportation.

Why is choosing a reputable freight carrier crucial?

It’s reasonable to say that if you own a physical store or an online store, shipping logistics are essential to your survival. Making the incorrect decision could mean the difference between success and failure.

Your freight career's dependability, efficacy, and cost-effectiveness are crucial components of your machine. Without it, your business may suffer significant losses, and as most people don’t distinguish between businesses and their shipping methods, the collapse of said freight career will compromise the integrity of your business. If you’re a B2B or B2C customer and you’re expecting a specific good or product, and the delivery is delayed or handled improperly, who do you blame?

What choices are there for freight?

There are many options to pick from when it comes to freight.

The following aspects are often taken into consideration while selecting a certain option: distance, shipping volume, cost, and timing. There is a freight alternative that works for every operation while keeping these crucial considerations in

mind.

Full truckload (FTL)

FTL refers to freight in full truckload. A freight firm that does this kind of transportation will commit an entire vehicle to the consignment of just one company. This indicates that only items belonging to one company will go from the point of origin to the destination. Transit time is one of the major advantages of TL shipping because there won’t be any additional pauses to unload the item. It will go directly from

the point of origin to the location the business wants, which can significantly speed up the process.

Less than truckload (LTL)

This indicates that a company's consignment requires less space than the truck can provide. Instead, it stores more freight to fill it to capacity (typically products or goods offered by a different company that are in transit to the same location). Since LTL shipping relies on a hub-and-spoke network with numerous access points, loading and unloading zones, and connecting trucks, it is more complicated than TL shipping. This lengthens the travel time and increases the quantity of handling the shipment will experience. However, it can significantly alter the cost of the shipping by making use of time, resources, and capacity. When it comes to quality, LTL has a give-and-take relationship.

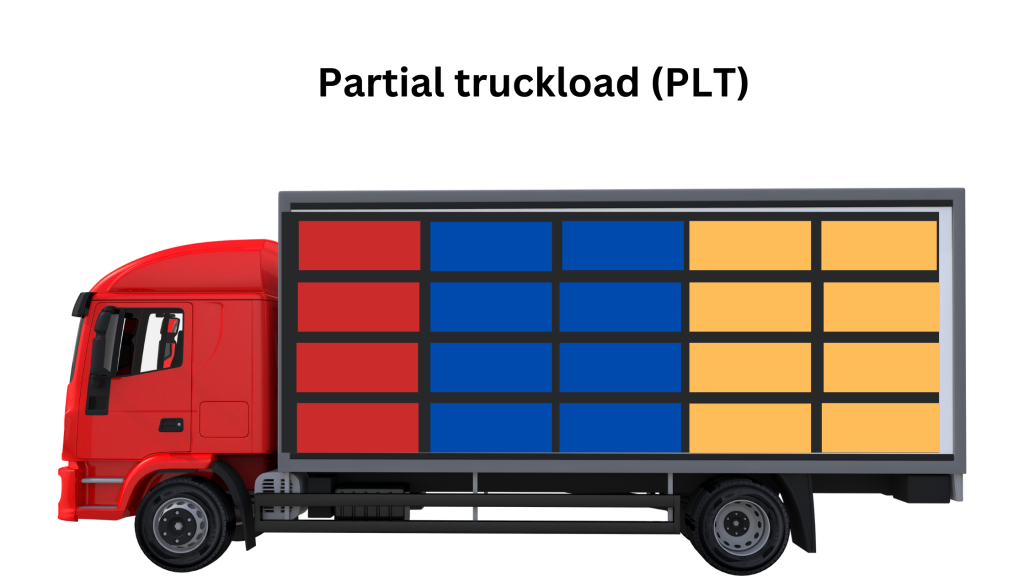

Partial truckload (PLT)

Partial truckload freight is referred to as PTL. Most of the time, it resembles a cross between TL and LTL.

A shipment must essentially meet three criteria in order to be classified as PTL: it cannot be a vulnerable or sensitive shipment; the volume must be more than LTL; and there must be some wiggle room in the transit time. In essence, a truck will accept a half-truckload of several goods and deliver them one after the other. You would assume that PTL shipping entails a lot more handling (unloading and loading) of a specific item. However, PTL shipments, on average, go through fewer hands than PTL shipments.

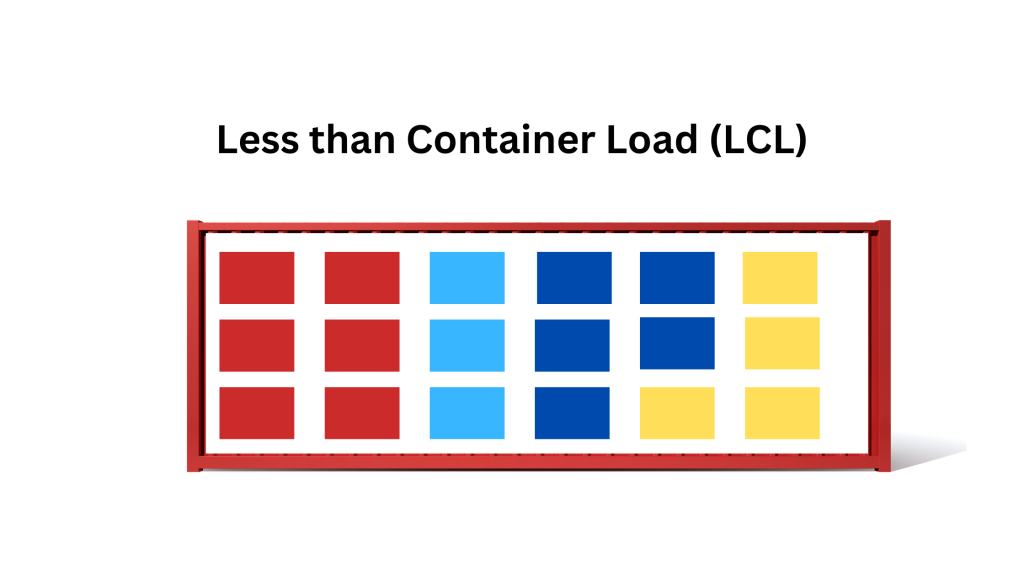

Less than Container Load (LCL)

A Less than Container Load, or LCL, as it is known in the shipping industry, refers to small ocean freight

shipments where the shipper does not contract for a complete container since the quantity of the shipment is insufficient to do so. Multiple LCL shipments may be combined at a CFS (container freight station) by a freight forwarder to generate a “Consolidation” which is then gated into a CY (container yard) at the origin and deconsolidated at the destination.

LCL shipments are more convenient to book during busy times and peak season than FCL shipments. Low volume goods may be handled simply, and LCL shipping is a far more affordable choice. Additionally, LCL shipping is a significantly less expensive option when the shipment is not urgent.

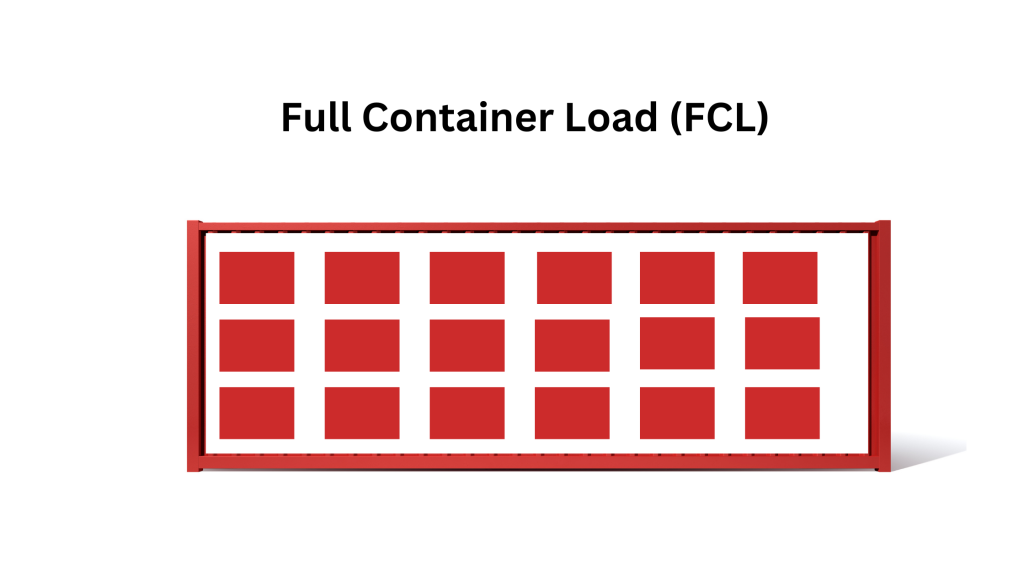

Full Container Load (FCL)

A shipment is classified as a “full container ” when the cargo fills the entire container. Even though the container may not always be completely filled, the fee is calculated based on a full container.

The typical shipping method for a large load is FCL. One shipper owns the items in the container, which also includes one Bill of Lading (BOL).

The different stages of FCL/LCL shipment:

- Trucks are used to deliver the shipment to the port of departure.

- The products are cleared by customs.

- The items are taken out of the truck and put into a container.

- The cargo ship is loaded with the container.

- The cargo ship reaches the Chinese port of call.

- The container is discharged at the port.

- The box is opened, and the packages are divided up into their many receivers.

How does a freight carrier set its rates?

The shipping industry’s rule of thumb is that size and weight make up the greatest factors that decide how much your shipment will cost. However, there are exceptions to this rule, but they are rarely a reality. With that being said, the distance travelled can drastically affect the price also. You may not have a large package, but if it needs to move across the country, then it’s reasonable to conclude that the transit time will considerably affect your final cost. Lastly, the sort of goods or goods being transported can contribute as well, particularly if they’re deemed sensitive.

Each shipping method will have its own freight class. The final price will also be affected by this. The weight (also known as density), kind of packaging, total value of the shipment, and sensitivity—or, in other words, the vulnerability—of a certain product or object being damaged during the shipping process are the main criteria used to classify freight. In an oversimplification, the chances are that you

will pay more overall if you are transporting something that you would identify as fragile.

Finally, the dimensional weight is a significant component in determining how much a shipment will cost overall. To determine this measurement, freight firms use a common formula across the board. Here’s an illustration to help individuals who don’t comprehend dimensional weight: I imagine you have a lot of ready-made balloons that you're transporting. You place them in substantial boxes that fill a truck to the brim. Their weight is light in comparison. This dimensional weight will be a cost consideration and something to take into account.

Conclusion

The freight sector is intricate, intertwined, and difficult to comprehend. The machine is turned by a variety of gears, and businesses that have focused on just one aspect of its multi-layered design have had great success. Freight carriers used to be the most well-known term in the industry, but now people know that they are businesses that specialise in providing machinery to move goods or products.